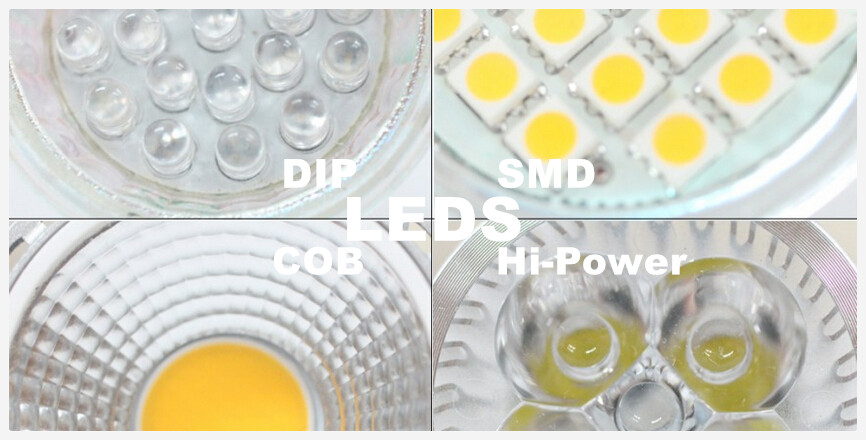

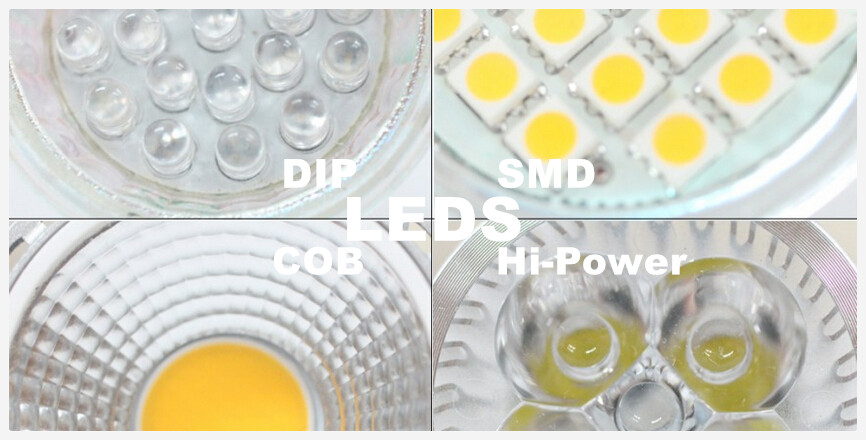

LEDs - DIP vs SMD vs COB

LEDs - DIP vs SMD vs COB

There are other types of LED available and new technology is developed every day, here just introduce to you follow main types.

DIP – Dual In-line Package

SMD – Surface Mounted Diode

COB – Chip On Board Chip-on-Board

DIP LEDs

Originally, the legacy design of LEDs that most people are familiar with is Dual In-Line Package (DIP) LEDs, which was developed by Nick Holonyak in 1962.

Hi-power LEDs are in a way, the “bigger brother” of the DIPs. In general, DIPs require 20/21 diodes to hit 1 Watt. A single Hi-Power LED is 1 Watt and coupled with the 38° beam angle, it can generate a very intense light output. Hi-Power LEDs are ideal for highlighting certain areas for both functional purposes and decoration. They are commonly used in wall washers and uplighters for this reason.

SMD LEDs

Compared to DIP LEDs, SMD LEDs appear more flat, come with a longer lifespan and consume up to 75 percent less energy. SMD chips incorporate more contacts than DIP LEDs – sometimes up to four or six, depending on the number of diodes per chip. In application, this type of packaging style is commonly found in strip lighting, indicator lights, LED high bay lights and LED flood lights, producing roughly six lumens per diode on the chip.

SMD LEDs are known for low maintenance and production costs; however, there are some flaws in their design. The packaging style does not manage space well, as several gaps can be seen in between each chip. This is not effective for extremely compact lighting systems, such as luminaries for intricate machines and tools. This issue, along with weak heat dissipating features, are addressed in the latest LED packaging style: COB.

COB LEDs

The limitations of SMD LEDs have ushered in the era of COB LEDs. To start, the modern packaging style is capable of accommodating nine or more diodes per chip, greatly improving their illuminative qualities. Moreover, this type of LED only relies on one circuit and two contacts – without consideration for the number of diodes (single circuit design). The configuration on the panel also appears more condensed, which translates to multi-directional lighting, or uniform light in all directions. A major drawback in using this type of packaging style is the lack of color-changing features.

When it comes to manufacturing, COB LEDs can be up to 10 percent cheaper to produce than SMD LEDs. For the latter, labor and material costs make up around 15 percent of the total manufacturing cost, while COB LEDs only require 10 percent.

Lastly, COB LEDs are less prone to failure when operating in hot environments, compared to SMD LEDs. This is a huge advantage for industrial facilities that work with high temperatures on a regular basis.

Tips

All beam angles are measured from a flat surface. LEDs in spotlights may have a slightly different beam angle due to the shape of the bulb, therefore it may be wise to check the beam angle on the product page before purchasing.

View More Liteharbor Products >>> http://www.liteharborfactory.com/products/

RESOURCE

RESOURCE